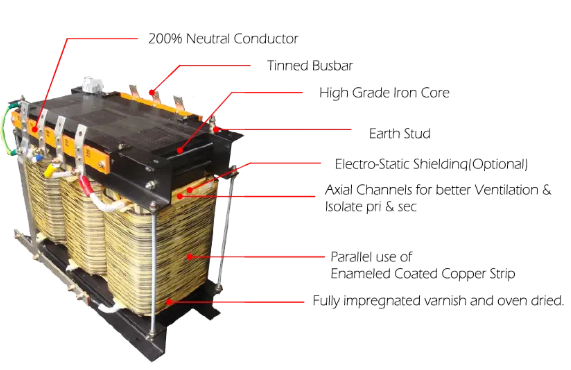

HV and LV Winding

Fully automated high tension and low tension copper winding process ensures fast and compact coiling of MNS transformer.

Cut to Length Core Processing Line

MNS CNC operated Cut to length core cutting and core stacking line allows us rapid production

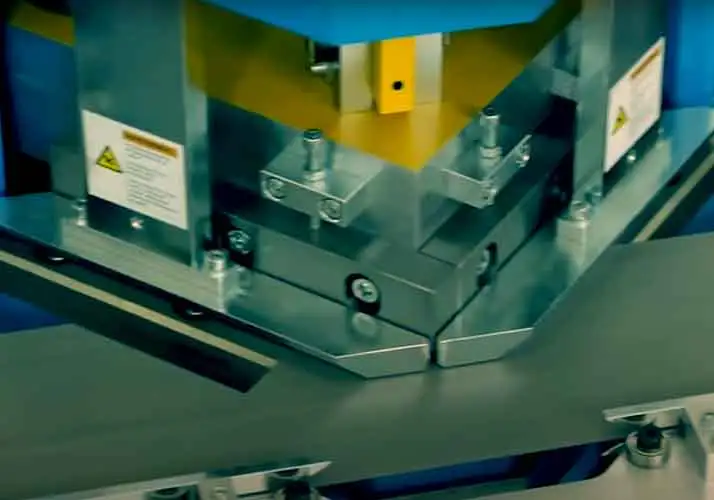

Automatic Fin Processing System

MNS CNC operated automatic Fin processing and welding process makes our Transformer tank welding State of Art.